Description

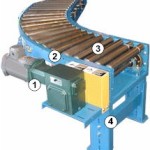

CDLR Conveyor – Model CDLR35

CDLR Conveyors provide positive drive with their sprocketed roller system. Chain driven live roller conveyors are excellent for moving pallets, drums, tires, and heavy loads at controlled speeds.

Roller Centers: 6.00”, 7.50”, 9.00” or 12.00”, with 60A20 sprockets.

Effective Widths: 13”, 25”, 37”, 45”, 49”, 54”, 57”, 61”, 67” and 73”. Also available from 6” to 81” in 1” increments.

Lengths: Even increments of the roller centers up to 80’. Length also limited to 75 rollers on each of the drive.

Drive: Standard D16 – side, bottom, near center with live axle drive roller. Drive has cast iron worm gear speed reducer with a standard M07 1 H.P. 230/460 TEFC motor.

Speeds: Standard 30 feet per minute. Also available from 1 to 120 feet per minute.

Rollers: Standard 3.5 dia., .300” wall tubes with 1” hex cold rolled steel axles, cotter pin retained. Standard A80 bearings are grease lubricated. Double shielded.

Frame: Standard F27 8” @ 11.5 lb. structural channel on chain side, 6” @ 8.2 lb. structural channel rollers set high on idler side with bolted 5” @ 6.7 lb. structural channel crosstie.

Chain Covers: 3/16” steel with two piece construction for easy access to chain loops.

Supports: SPHH style adjustable set for standard 36” top of rollers located on nominal 5’ centers. Also available from 11” to 42” top of roller at no additional charge.

Capacity: Up to 2,500 lbs. per lineal foot of conveyor with supports on 5’ centers. Consult the factory to evaluate specific applications.

Guard Rails: Standard G99: No Guard Rail.

Roll Covers: Standard V98: No Roll Cover.

Finish: Standard PP94: Safety Blue, Epoxy Powder Coat.