Description

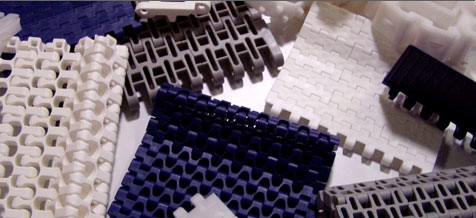

Modular Plastic Belting for conveyors

Modular Plastic Belting for conveyors whether it is raw, frozen or hot cooked food, packages, printing hot off the press or loose materials can transfer your product between processes. Some belt types have varying accessories such as tabs, product supports, side guides and finger plates.

For many applications, especially in the food industry, plastic modular belting is an excellent addition to the conventional conveyor belt product range. The material is rot resistant, durable and safe. Cleaning of the belts is simple and unproblematic.

Materials:

The standard grades of the plastic belting are:

Polyoxmethylene (POM) withstanding temperatures from -40 to 90 degrees C, a thermoplastic self lubricating material with resistance to some chemicals, wear and has good strength elasticity and stability;

Polypropylene (PP) withstanding 1 to 104 degrees C, an economical material for applications with high temperatures, also has good resistance to some chemicals; and

Polyethylene (PE) withstanding -50 to 80 degrees C, an economical material for applications with low temperatures.

Special materials are also available for their superior abilities glass reinforced, anti-static, high heat resistant, high wear resistant, high impact resistant, acid resistant, high chemical resistance and flame retardant.