Description

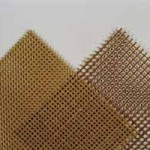

Porous (27 Series)

|

The DuraFlow® Porous Belts are specially formulated to be “breathable,” while at the same time, maintaining their unique non-stick properties. These belts are manufactured from woven fiberglass substrates that have been lightly coated with PTFE (Fluon®). The DuraFlow® Porous Belts possess controlled porosities that allow products to cure and outgas through the fabric. These unique properties make these belts ideal for a wide variety of applications from the manufacture of sponge and foams to the manufacture of wood laminates. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

DuraFlow® PTFE Coated Belt Characteristics |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

DuraFlow® Belts are engineered to retain the distinctive properties of PTFE; however, by adding a glass fabric to the matrix, AFC is able to obtain the added benefits of dimensional stability, excellent tensile strength and extremely low elongation (<1%). DuraFlow® Belts have received USDA approval for food processing and handling, and are FDA compliant (21 CFR177.1550). In addition, the DuraFlow® belts can operate in temperatures from -400°F (-240°C) under static conditions and -100°F (-73°C) under dynamic conditions up to 550°F (288°C). |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Typical Applications |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Packaging:

Food Products:

Printing and Textiles:

|

Polymer Processing:

Building Products:

Other:

Additional applications exist. Contact AFC for more specific information. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Styles Available |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||