Description

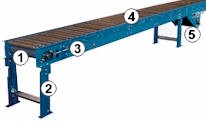

Belt Driven Live Roller Conveyor – Model BDLR19

Belt driven live roller conveyors are designed to handle products like drums, pails, tires, bundled cardboard or boxes of various size and weight. The design of the belt driven live roller conveyor allows minimal pressure accumulation with 1.9″ dia., rollers on close centers. The accumulation pressure is adjustable by means of tension rollers mounted underneath.

Standard Specs:

Carrier Roller: 1.9 dia., 16 ga. wall tubes with 7/16 hex cold rolled steel axle, spring retained. Standard A11 bearings are greased packed.

Roller Centers: 2.00”, 3.00”, 4.00”, and 6.00”.

Tension Roller Centers: Always two times the carrying roller center. Example: 3” centers – pressure roller centers would be 6” centers. Pressure rollers are mounted in adjuster plates for adjusting the pressure exerted on the carrying rollers above.

Belting: Standard B06 PVC-120 black, friction surface. Belt is shipped laced and installed on conveyors up to 10’ long. On all other conveyors the belt is shipped loose with lacing installed for field installation.

Between Frame: Standard 15”, 19”, 21”, 25”, 27”, 33”, 37”, and 39”. Also available from 6” to 39” in even 1” increments.

Belt Width: 6” wide on 13” through 39” between frames.

Lengths: 5’ to 100’ in even 1” increments.

Drive: Standard D02 – center, right hand side. Drive has cast iron worm gear speed reducer with standard M99 1/2 H.P. 230/460 volt TEFC Motor.

Speed: Standard 60 feet per minute. Also available from 10 to 120 fpm.

Bearings: Sealed Pre-lubricated, cast iron flange ball bearings.

Frame: 7-1/4” x 1-1/2” x 1/8” formed steel channels with bolted 2” x 3/16” galvanized angle lower cross ties and bolted 1 1/2 x 1/8” angle upper crossties.

Drive Pulley: Standard 8” dia. with 1-7/16” dia. shaft crowned and lagged. Mounted in 2 bolt flange bearings. Note: Used on D02 & D03 drive options also on conveyors 51’ and longer. 4” dia. with 1-3/16” dia. shaft crowned and lagged, mounted in 2 bolt flange bearings.

Take-up Pulley: 4” dia. with 1-3/16” dia. shaft, crowned and lagged, mounted in 2 bolt flange bearings.

Snubber Rollers: Standard 2.5 dia. 11ga. wall tubes with 11/16” hex cold rolled steel axle, spring retained. Standard A55 bearings are greased packed with front and back seals. Used on conveyors with D02 & D03 center drive. 1.9” dia. 12 ga. wall tubes with 7/16” hex cold rolled steel axles, spring retained. Standard A23 bearings are greased packed with front and back seals.

Tension Rollers: 1.9 dia., 16 ga. wall tubes with 7/16 hex cold rolled steel axle, spring retained. Standard A11 bearings are grease packed. The same for return rollers.

Capacity: 200 pounds per lineal foot. Total load not to exceed capacity shown in chart.

Supports: SPHH Style adjustable set for a standard 36” top of roller located on nominal 10’ centers. Also available from 7.5” to 42” top of roller at no additional charge.

Roll Covers: Standard V98: No Roll Cover

Finish: Standard PP94: Safety Blue, Epoxy Powder Coat.